Frequently Asked Questions of Cold Galvanizing Coating

Galvanized steel is carbon steel varnished with zinc. Zinc coating is most widely used in the hot-dip process. The hot-dip process involves submerging the carbon steel in a bath of molten zinc.

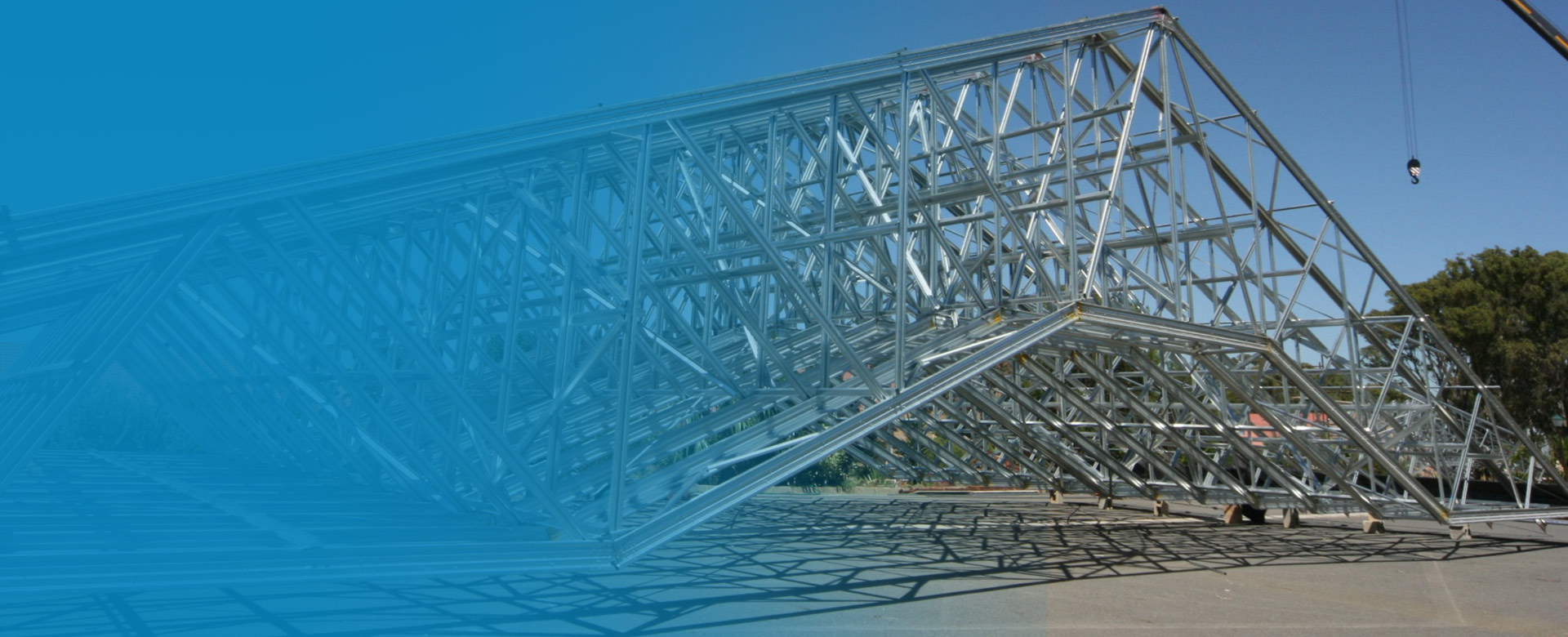

The galvanizing step of the process occurs when steel is completely immersed in a bath of molten zinc. The bath chemistry must be at least 98 per cent pure zinc and held at a temperature of approximately 840 F. The steel is lowered by crane hoist at an angle. The method of galvanizing consists of three basic steps: surface preparation, galvanization, and inspection.

Hot dip galvanized coatings are often cost dependent on the weight of galvanized steel which weights the products after galvanizing. An agreed price per unit may be negotiated for contract-galvanized products to facilitate invoicing and minimize repetitive handling in the galvanizing process.

Galvanized steel costs more than standard structural steel a few cents per pound. Stainless steel costs four to fifth times as much in production prices as galvanized steel. Structural steel holds between 30 to 80 cents per pound whereas stainless steel holds a minimum of $3 per pound.

Hot-dip galvanizing, the electrochemical reaction, is a chemical procedure. Cold galvanizing is the physical address, just brush the zinc surface layer, the zinc layer is quick to decay. Construction to use galvanizing by hot dip.

Galvanizing, also known as galvanized hot-dip, it is the ingot melted at high temperatures, a variety of additional material in place, and dipped galvanized metal structure hole, the metal part on a zinc sheet. The advantages of hot-dip galvanizing corrosion with its zinc coating strength, adhesion and toughness are better.

The zinc coating of hot-dipped galvanized steel will last for 35 to 50 years in the toughest soil, and 75 years or more in less corrosive soil. Although humidity affects corrosion, temperature itself does have less effect. At extreme cold and hot temperatures galvanized zinc coatings react well.

While cold galvanizing does not live up to the performance of hot-dip galvanizing, it does have its benefits. Cold galvanizing is ideal for cost-effective and rapid application on smaller structures and components.

.png)