Anti Corrosion Coating and Paint

The corrosion resistance coating prevents metal parts from damage due to humidity, salt spray, oxidation or exposure to a range of environmental or industrial chemicals. Anti-corrosion coating provides additional metal surface protection, which serves as a barrier to prevent interaction between chemical compounds or corrosive materials.These also have an abrasion resistance bonus, non-stick efficiency, and chemical protection. This coating provides a high level of corrosion protection for industrial parts which operate in extremely corrosive environments.

Anti-corrosion paint for metal is an important tool in combating the oxidation battle. Used onEquipment’s, Control Panels, MS Structures, Structural Steel, Transformers, Chemical Plants/ Refineries, Industrial Valves, Pipe Lines, Marine & Shipping, Motors & Pumps, Storage Tanks, Thermal Power Complexes, it protect structures in some of the harshest environments. For anti-corrosive coatings, there are several advancement areas. Key markets include oil and gas, power, industrial and infrastructure, PEB Structures, Chemical Plants, Fire Resistance Structures, Transformers, and Marine& Shipping.

Also on a steel surface with a protective anti corrosion paint, water will inevitably find a way to push for underlying metal. Due to our reliance on steel bridges, vehicles, water heaters and other steel goods, the resulting oxidation is very costly for the society.

ANTI CORROSION PAINT

Anti-corrosive protective coating to replace traditional Epoxy & Polyurethane paints

ANTI CORROSION - FR

Anti-corrosion fire retardant protective coating to protect metallic structures from fire & corrosion under varying climatic conditions.

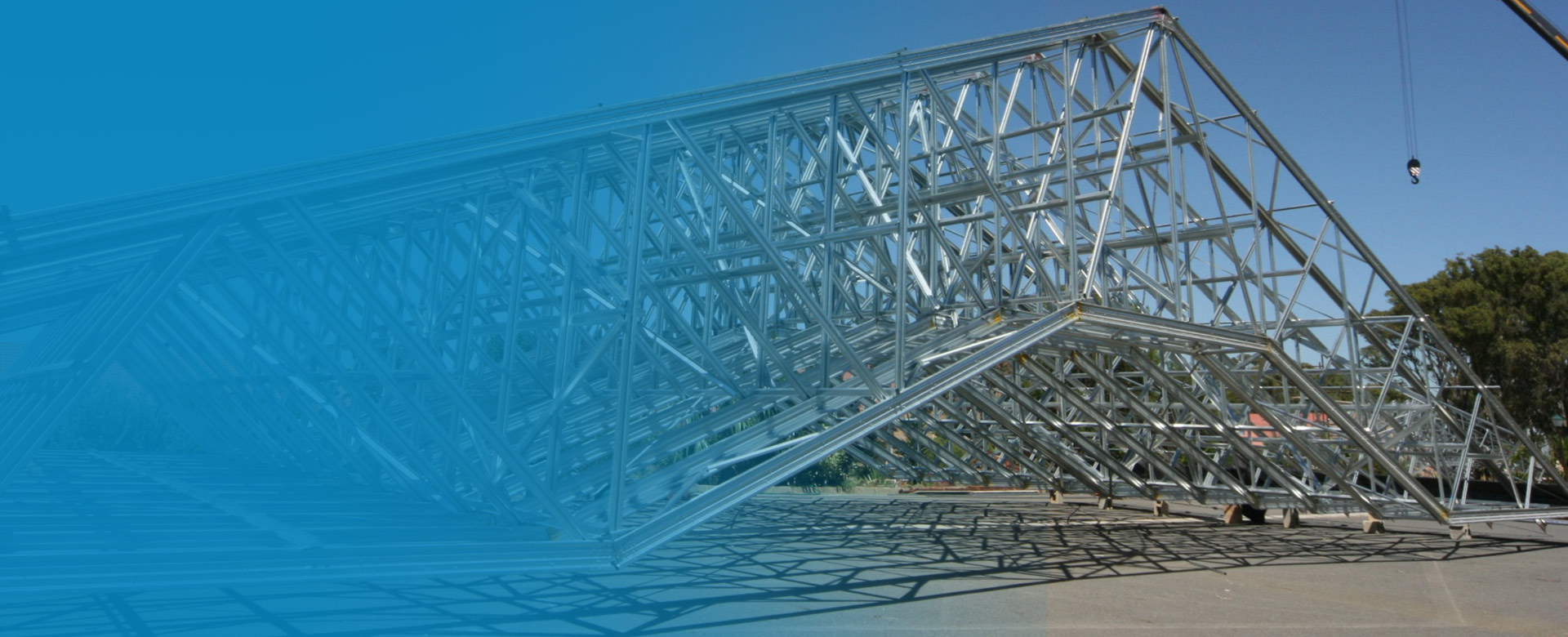

PEB Structures

ANTI-CORROSION - MRN

High performance corrosion resistant coating for Marine and Shipping applications

ANTI-CORROSION - CRC

Protective Coating for highly corrosive chemical environment

UNIQUE FEATURES OF Anti Corrosion Coating

- Quick Drying at room temperature : Dries within 15 minutes at room temperature.

- ROHS Compliant.

Chemical Plants

Fire Resistance Structures

PERFORMANCE FEATURES

- Excellent Resistance to Corrosion

- Excellent resistance to U.V Radiation

- Resistance to Acids, Alkalies & saline atmosphere.

- Stable up to 200OC

- Tough & Scratch proof Available in all necessary shades of color

BENEFITS OF ANTI CORROSION PAINT

- Enhanced performance properties - Longer life cycle

- Single Pack, Ready to use system - Easy Apllication Process

- No wastages - Clean Enviroment

- Fast drying at room temperature-Performance increased, rapid output & displacement, reduced downtime

- No need of Oven Baking - Energy Saving

- Saves Lobor, Saves time, Saves energy, Saves Space

Transformers

Marine & Shipping

APPLICATIONS

- Equipments

- Controal Panels

- MS Structures

- Structural Steel

- Transformers

- Chemical Plants/ Refineries

- Industrial Valves

- Pipe Lines

- Marine & Shipping

- Motors & Pumps

- Storage Tanks

- Thermal Power Complexes

Anti Corrosion Coating & Paint Manufacturer Supplier in Nashik, Pune, Aurangabad, Ranjangaon, Faltan, Kurkumbh, Pimpri Chinchwad, Chakan, Khed Shivapur, Shikrapur, Walunj, Chikhal Thane, Shendra, Surat, Hazira, Palsana, Vapi, Silvassa, Dhanej, Kosamba, Baroda, Halol, Ahmedabad, Jamnagar, Gandhidham, Mundra, Sanand India

Frequently Asked Questions of Anti corrosion Coating

Yes. Anti corrosion protective coating allows additional metal surface protection, and acts as a barrier to inhibit contact between chemical compounds or corrosive materials. It can protect metal components from corrosion because of humidity, salt spray, oxidation or exposure to a range of environmental or industrial chemicals. This anti corrosion paint provides solid corrosion resistance up to 9-10 years. Sometimes the life of coating depends on composition of the coating; this consists of binders, pigments, solvents, extenders, and additives as well as several external environmental parameters.

Coating a metal surface with paint or enamel creates a barrier in the atmosphere between the metal and the humidity. The method of oxidizing a metal surface with another metal is referred to as a sacrificial coating.

There are a variety of internal and external factors that influence the corrosion process. Internal factors are those that are tied to metal, such as: steel structure, surface condition, surface presence of protective films, processing method, etc. When the iron surface is covered with more active metal layers than iron, the corrosion rate is delayed. Some main factors which affect corrosion are impurities in metals, electrolyte in water, and carbon dioxide in water.

.png)