HEAT REFLECTIVE COATING AND PAINT - HEATSEAL

Heatseal promises to reduce transfer of heat reflective coating from outside to inside and makes the houses, working places, flooring etc. comfortable by keeping them cool in summer.

It is an innovative polymer-based research technology that can dramatically reduce the energy consumption and expense of cooling a home, factory, steel building, industrial or commercial structure by maintaining the interior cooler at least 100C in summer.

To ensure thermal comfort in the built environment, our heat reflective paint for building surfaces applied on the roof / walls can be very useful in minimizing heat and cooling loads.

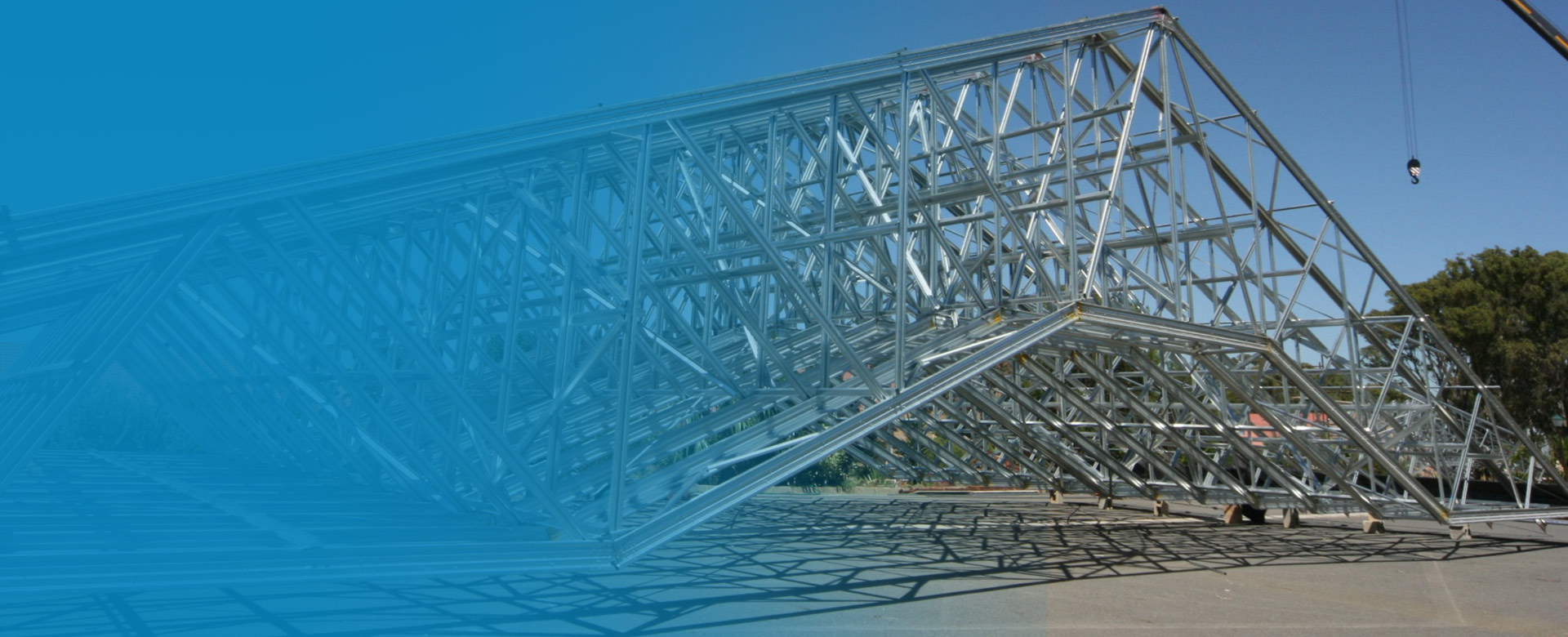

Concrete Surfaces

PEFORMANCE FEATURES HEAT REFLECTIVE COATING :

- Excellent Resistance to U.V.Radiations

- Excellent Abrasion Resistance

- Excellent water repellancy and moisture resistance.

- Quick Drying at room temperature

- Excellent Resistance to chemicals

- Excellent Outdoor Stability

Heat Reflective Coating and Paint Manufacturer Supplier in Nashik, Pune, Aurangabad, Ranjangaon, Faltan, Kurkumbh, Pimpri Chinchwad, Chakan, Khed Shivapur, Shikrapur, Walunj, Chikhal Thane, Shendra, Surat, Hazira, Palsana, Vapi, Silvassa, Dhanej, Kosamba, Baroda, Halol, Ahmedabad, Jamnagar, Gandhidham, Mundra, Sanand India

Refrigerated Vans

ADVANTAGES OF USING HEAT REFLECTIVE COATING

- Comfortable interior atmosphere

- Less utility bills

- Energy sustainability

- Lasting roof materials

Heat Reflective Coating and Paint Manufacturer Supplier in Nashik, Pune, Aurangabad, Ranjangaon, Faltan, Kurkumbh, Pimpri Chinchwad, Chakan, Khed Shivapur, Shikrapur, Walunj, Chikhal Thane, Shendra, Surat, Hazira, Palsana, Vapi, Silvassa, Dhanej, Kosamba, Baroda, Halol, Ahmedabad, Jamnagar, Gandhidham, Mundra, Sanand India

BENEFITS OF HEAT REFLECTIVE PAINT

- Due to the continuous rejection of solar heat by this paint, the heat emitted from the roof such as UV and infrared rays is significantly reduced and these rays are reflected back into the atmosphere.

- For the false ceiling, it eliminates the necessity.

- On any roof material or sidewall, this paint can be coated.

- This paint helps in reducing global warming and greenhouse gas emissions.

- Cool roof surfaces in hot and humid locations may be more susceptible to algae growth.

- It can be cleaned with water as it does not contain solvents.

- This paint does not contain any toxic substances.

Heat Reflective Coating and Paint Manufacturer Supplier in Nashik, Pune, Aurangabad, Ranjangaon, Faltan, Kurkumbh, Pimpri Chinchwad, Chakan, Khed Shivapur, Shikrapur, Walunj, Chikhal Thane, Shendra, Surat, Hazira, Palsana, Vapi, Silvassa, Dhanej, Kosamba, Baroda, Halol, Ahmedabad, Jamnagar, Gandhidham, Mundra, Sanand India

Frequently Asked Questions of Heat Reflective Paint

A white roof is coated with heat-reflective white coating which reflects up to 90% of sunlight. White roofs are much more than just white paint it is an indicator of the ability of a surface to reflect solar heat.

Heat Reflective Paint. It improves the insulation properties of buildings in an environmentally friendly manner. Generally, these paints are available in light colors because they can reflect up to 80% of the solar radiation.

Specialist heat reflective paints are also available, but their effect is minimal compared to going from dark to light colour. This coating allows more energy from the sunlight to bounce off than usual paint of the same colour. However compared to painting a dark roof with non-heat reflective light colored paint, the effect is only mild.

It is designed to reflect more sunlight and absorb less heat than a standard roof. The usage increases roof temperature and decreases room temperature correspondingly.

.png)